Seeking Steel And Stainless Steel Fabrication Services From A Custom Steel Supplier?

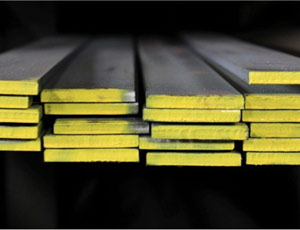

Steel fabrication is a process in which steel beams, flat bars, and other forms of raw steel are cut, drilled, punched, burned, welded, machined, or treated and modified, and eventually formed into a finished product. Various types of machinery, tools, and equipment are used in the fabrication process, including plasma cutting, break presses, drills, and saws, which will shape and modify stock materials for jobsite requirements.

Why Does Steel Need To Be Fabricated?

Fabrication is needed to convert a general-purpose raw material into a useful form with specific properties to suit a particular application, and steel fabrication is a vital part of any construction project. Steel beams, which are used to frame a building, are among the most common forms to be modified in the steel fabrication process. Additionally, the plates, bolts, and components that secure steel beams together are also formed through steel fabrication—as are tubing, angles, and other building elements that serve as an essential means of connection and support.

Steel Fabrication’s Role In The Past, Present, and Future

Older structures were once supported with cast iron. Once steel became an easily produced and affordable material, it quickly replaced cast iron as a primary structural material in most buildings and construction projects. Fabricated steel is found everywhere—from park benches to suspension bridges—for many good reasons; in terms of availability, economics, performance, longevity, and versatility, the choice of steel has yet to be bested for structural and industrial applications. Over the last century, infrastructure has risen and been held together by steel. As that same infrastructure is repaired and updated for the next century, steel remains the most appropriate, economic, and advantageous material on which to rely.

Steel Fabrication Vs. Stainless Steel Fabrication

When corrosion resistant properties and cosmetically pleasing finishes are needed, stainless steel fabrication is an optimal choice. Stainless steel is inherently resistant to rust and bears an attractive sheen. This can be especially favorable when parts and components will be visible, such as on the exterior of a building or for architectural and design-driven structures. Aluminum fabrication also yields forms that are cosmetically pleasing and resistant to corrosion. It also offers a high strength to weight ratio.

What Is A Fastener Supplier’s Role In Steel Fabrication?

When conventional beam and column steel fabricators need smaller scale, specialized steel fabrications, Baco Enterprises is where they turn. While we are a fastener supplier, we provide custom steel fabrication, custom aluminum fabrication, and custom stainless steel fabrication in addition to our delivery of bolts, anchors, and other construction and building components.

What Are Baco Enterprises Steel Fabrication Capabilities?

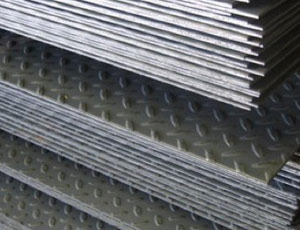

Baco Enterprises can provide steel fabrication for brackets, adaptor plates, clip angles, bearing plates, base plates, anchor bolts, and other products that are essential to a construction job. Plain, hot dipped galvanized, and painted finishes are available on all materials we fabricate. For over fifteen years, we’ve served as a custom steel and stainless steel supplier. We are proud to offer a timesaving and cost-effective solution for steel fabrication companies that need smaller and more specialized construction essentials as part of an overall job—and yet aren’t always practical for most fabrication shops to produce. We work with steel and stainless steel fabricators on projects throughout the greater New York Metropolitan area, and states throughout the Northeast and Mid-Atlantic, including New Jersey, Connecticut, Pennsylvania, Massachusetts, Rhode Island, Maryland, Delaware, New Hampshire, Maine, Vermont, and Virginia.

Avoid Common Mistakes When Sourcing Steel Fabrication

When sourcing steel fabrication services, such as stainless steel drilling, CNC precision machining and the construction of stainless steel bollards, it’s important to avoid the common mistake of confusing cost and value. Low cost steel fabrication services can often result in inferior quality parts and products. Mistakes made by low cost, or inexperienced steel fabricators will waste your time in manufacturing and installing which can add up to much higher costs than savings. It’s also important to consider what steel fabrication job quotes reflect in regards to an overall job. A significantly low quoted price may reflect sub-quality materials or fabrication services; it may also reflect a considerably longer lead-time. It can even reflect a misinterpretation or miscommunication of job specs.